reliability and process requirements to

the best low emission technologies

ERTA

More than sixty years of experience for industry.

Natural circulation water-tube boilers for saturated or superheated steam production.

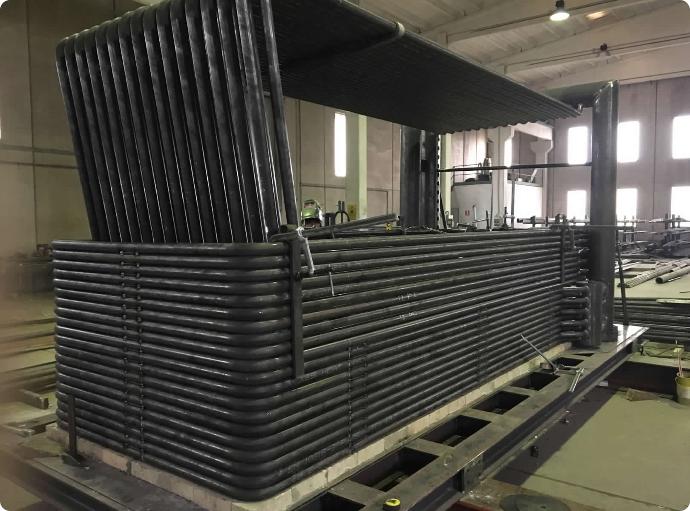

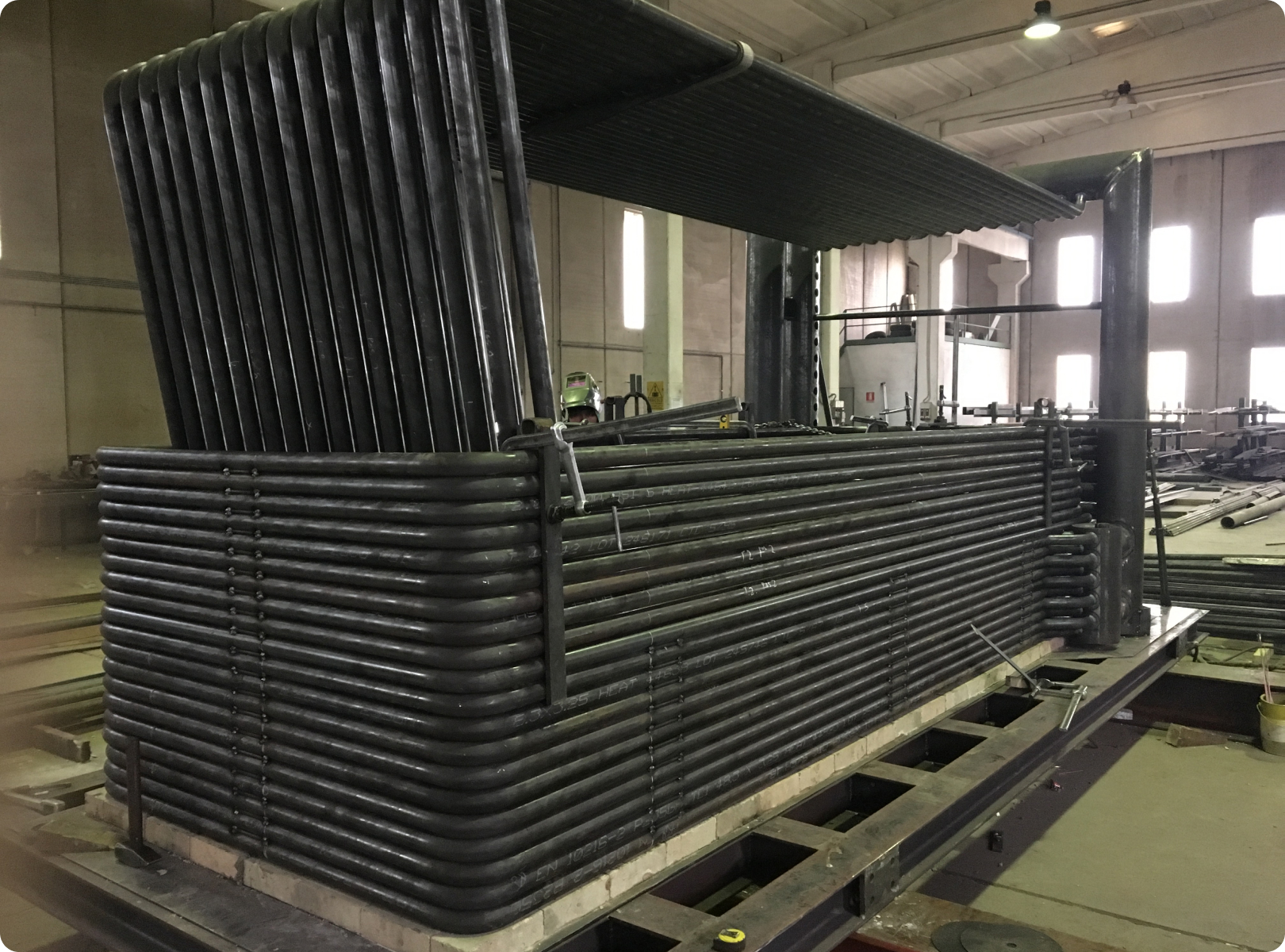

The medium to high pressure natural circulation water-tube boilers belonging to the ERTA series, for saturated or superheated steam production, represent the evolution of a project dating back to the middle of the last century with a classical “D-shape” configuration.The ERTA series, capable of operating with any kind of liquid or gaseous fuel, is composed of an upper and a lower steam drum, connected with expanded vertical water pipes, to which the flue gas flow, pressurized, runs in perpendicular direction.

The combustion chamber and the external surfaces consist of radiation screens, sized to obtain reduced surface thermal loads and composed of welded tangent tubes which maintain the flue gas circuit pressurization.

The convective bundle, depending on the fuel, can be equipped with a soot blowers automatic cleaning system, which ensure high performance and regular and long lasting operation.The “VSH” type includes a steam superheater to increase the temperature up to 510°C @ 80 barg max.The boilers can be combined with economizer(s) to heat up boiler feed water by means of the exhaust flue gas residual heat, increasing the thermal cycle overall efficiency.

Technical features:

|

|

ERTA-VS

|

ERTA-VSH

|

| PRODUCTION (t/h) |

Up to 60

|

Up to 60 |

| TEMPERATURE (°C) |

Sat. |

Up to 485

|

| PRESSURE (barg) | Up to 70 |

Up to 70

|

MT-F

Simple and compact boilers in industrial applications .

Multi-tube fired boilers for thermal oil heating.

The multi-tube thermal oil fired boilers of the MT-FD-F series are capable of operating with any kind of liquid or gaseous fuel.The easy-install box shaped boiler contains the combustion chamber, designed with low thermal loads, and the convective bundles. Insulation is obtained by means of tangent tubes external surfaces contained by mineral wool panels and cold casing which reduce refractory materials decreasing the thermal inertia for quicker start-ups and less maintenance.

The compact layout with integrated insulation, makes the MT- FD-F series a complete package, where technology and attention to the details are fully combined with a simple installation, operation and maintenance.The boilers can be combined with economizer or air preheater which increase the thermal cycle overall efficiency.

Technical features:

| MT-FD-F | |

| POWER (MW) |

Up to 15

|

| TEMPERATURE (°C) |

Up to 350

|

| PRESSURE (barg) |

Up to 15

|

PBSS

A century of development at the service of industry.

Shell boilers for hot or superheated water heatingand saturated or superheated steam production.

PBSS series shell boilers, for hot or superheated water heating and saturated or superheated steam production, are the summary of a secular experience and research.

The PBSS series is a three passes and wet back boiler type which combines high heat exchange and compact overall dimensions. The large-diameter eccentric furnace, corrugated or provided with expansion joints, guarantees an intense water circulation in the boiler, prevents local overheating and improves thermal exchange.

The tube sheets are rimmed and undergo a stress relieving heat treatment; all pipes are expanded and welded to the tube plates. The gas reversal chamber is completely surrounded by water, so that the maintenance costs for refractory are eliminated: the refractory materials in these boilers are in fact limited to the burner cone only.

The “VSH” model presents a convection superheater, which ensures maximum reliability even during start-up: it can increase the steam temperature up to 350°C.The boilers can be combined with economizer(s) to heat up boiler feed water by means of the exhaust flue gas residual heat, increasing the thermal cycle overall efficiency

Technical features:

|

|

PBSS-AC

|

PBSS-AS

|

PBSS-VS

|

PBSS-VSH

|

| POWER (MW) | Up to 15 |

Up to 15 | - |

- |

| TEMPERATURE (°C) | Up to 100 |

Up to 180 |

Sat. |

Up to 350 |

| PRESSURE (barg) | Up to 18 |

Up to 18 |

Up to 18 |

Up to 18 |

| PRODUCTION (t/h) | - | - | FUp to 20 |

FUp to 20 |

Contact us!

Fill in your data here. Our staff will be back to you soon.